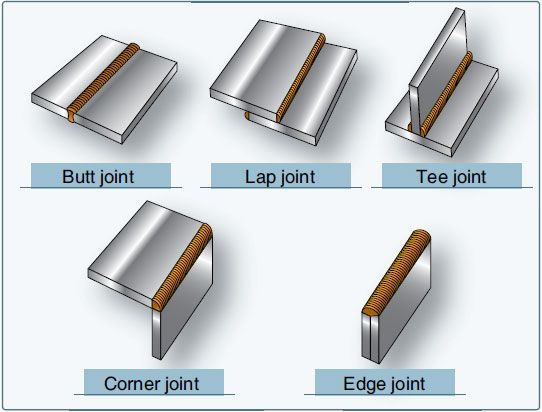

Different Types Of Welding Joints

1. Tee Welding Joint:- Tee welding joints are formed when two members intersect at a 90° angle which makes the edges come together in the center of a plate or component.

2. Lap Welding Joint:- Lap welding joints are used most often to joint two pieces with differing thicknesses together. Also considered a fillet type, the weld can be made on one or both sides.

3. Edge Welding Joint:- Edge welding Joints are often applied to sheet metal parts that have flanging edges or are placed at a location where a weld must be made to attach to adjacent pieces.

4. Corner Welding Joint:- Being one of the most popular welds in the sheet metal industry the Corner welding joint is used on the outer edge of the piece. This weld is a type of joint that comes together at right angles between two metal parts to form an L.

5. Butt Welding Joint:- Being the universally accepted method for attaching a pipe to itself it’s also used for valves, flanges, fittings, and other equipment. A butt welding joint is also known as a square grove weld.

6. Fillet Welding Joint:- Fillet Welded Joints are just another terminology for corner, lap, and tee joints. Fillet Welded Joints are the most common type of welding joint and accounts for nearly 75% of joints made with arc welding.

Comments

Sed eget lorem et risus vehicula ornare.

A H Khan

Updated 7 years agoNam eleifend enim eu sollicitudin faucibus.

Admin

Updated 7 years agoVestibulum sodales nisi at varius dapibus.

R K PATEL

Updated 7 years agoIn condimentum libero a risus mattis eleifend.

Admin

Updated 7 years agoNullam tincidunt velit sit amet enim mattis, in porta ipsum finibus.

J K JOSHI

Updated 7 years agoMorbi pellentesque lacus in nibh fermentum, eget fermentum turpis accumsan.

Admin

Updated 7 years agoCras non augue ullamcorper, elementum ipsum dictum, euismod ex.

K H DAVE

Updated 7 years agoVestibulum venenatis ipsum vitae risus auctor finibus.

S K Anand

Updated 7 years agoEtiam non est tristique, tristique nibh quis, fringilla elit.

Admin

Updated 7 years agoAenean consequat mauris quis libero maximus pellentesque.

R G Pathak

Updated 7 years agoPellentesque non lacus et libero venenatis vehicula.

Quisque sit amet neque et ante tincidunt faucibus.

T PATEL

Updated 7 years ago