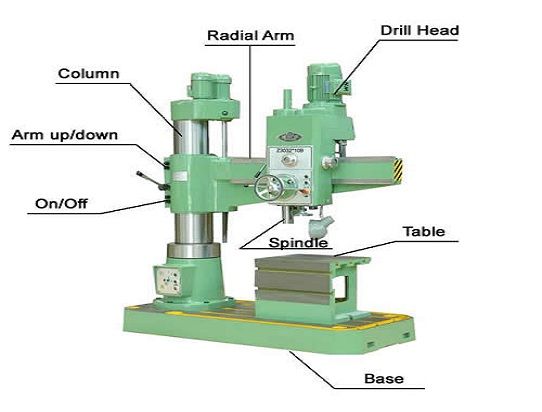

Components of Drilling Machines

The main operating parts of a sensitive machine/drill press are Base, Column, Table, and Drill Head.

1. Base: The base is a heavy casting that supports the machine structure; it provides rigid mounting for the column and stability for the machine. The base is usually provided with holes and slots which help to Bolt the base to a table or bench and allow the work-holding device or the workpiece to be fastened to the base.

2. Column: The column is a vertical post that Column holds the worktable and the head containing the driving mechanism. The column may be of round or box section.

3. Table: The table, either rectangular or round. Drill machine/press in shape supports the workpiece and is carried by the vertical column. The surface of the table is 90- degree to the column and it can be raised, lowered and swiveled around it. The table can be clamp/hold the required the workpiece. Slots are provided in most tables to allow the jigs, fixtures or large workpieces to be securely fixed directly to the table.

4. Drilling Head: The drilling head, mounted close to the top of the column, houses the driving arrangement and variable speed pulleys. These units transmit rotary motion at different speeds to the drill spindle. The hand feed lever is used to control the vertical movement of the spindle sleeve and the cutting tool.